Box Girder vs. Truss Girder: The Ultimate Guide to Main Beam Selection for Electric Hoist Gantry Cranes

Selecting the right main beam is critical for electric hoist gantry crane performance. As the backbone of your gantry crane, both box girders and truss girders impact efficiency and durability. This guide delivers a data-driven comparison to optimize your gantry crane investment.

Core Structural Comparison: Design Principles Define Performance Limits

| Parameter | Box Girder | Truss Girder |

|---|---|---|

| Structure | Closed steel welded box | Open triangular truss framework |

| Weight (20T class) | Heavier (~8-12T) | 30% Lighter (~5.5-8T) |

| Torsional Rigidity | ★★★★★ (High integrity) | ★★★☆☆ (Requires bracing) |

| Ideal Span | Medium spans (12-30m) | Long spans (ssshhh30m optimal) |

Critical Selection Criteria: 5-Dimensional Analysis

1. Load Capacity & Stability

Box Girder: Superior moment of inertia minimizes deflection (≤ Span/700), ensuring smoother electric hoist operation

Truss Girder: Susceptible to vibration under dynamic loads; dampers often required

2. Spatial Efficiency

Low Headroom: Box girders typically reduce height by 15-20% vs. truss designs

Obstruction Clearance: Truss girders allow easier utility routing (e.g., cable trays in PV plants)

3. Lifecycle Cost Analysis

| Cost Factor | Box Girder | Truss Girder |

|---|---|---|

| Initial Investment | Higher | 25% Lower |

| Corrosion Maintenance | Easy surface protection | Complex joint treatment |

| Energy Consumption | ~8% Higher | More Efficient |

4. Environmental Resistance

Dusty/Humid Environments: Box girders better protect internal electric hoist mechanisms

Outdoor Corrosion: Truss joints require specialized coatings (hot-dip galvanizing/thermal spray)

5. Installation & Scalability

Installation Speed: Truss girders assemble 40% faster via modular components

Upgrade Potential: Box girders simplify sensor integration (strain gauges/vibration monitors)

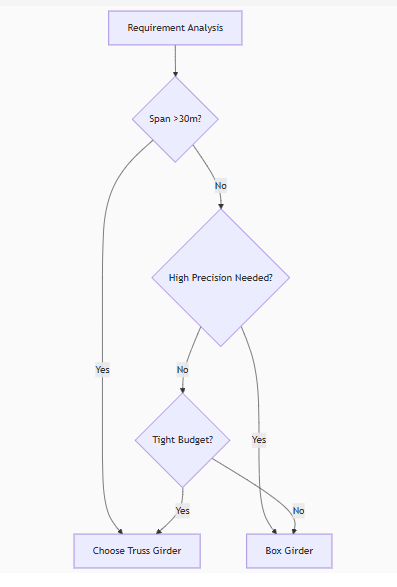

Decision Flowchart: 3-Step Selection Protocol

Gantry Crane Applications:

Box Girder: Precision manufacturing gantry cranes (10-25m)

Truss Girder: Logistics yard gantry cranes (ssshhh35m spans)

Industry Evolution: Hybrid Solutions

Innovative dddhhhBox Girder + Truss End Beamdddhhh hybrids deliver:

Box girder ensures electric hoist stability

Truss end beams reduce deadweight (18% lighter overall)

Case Study: 32m span electric hoist gantry crane cuts energy use by 22%

Match the Beam to Your Operational

The box girder vs. truss girder decision balances rigidity, cost, and space. Key takeaways:

Precision operations: Box girders for heavy-duty/high-frequency relability

Long-span economy: Truss girders maximize weight savings

Hybrid designs: The premium choice for modern electric hoist gantry cranes

Optimize your crane design → [Beam Selection Calculator](Your Product Link)